Our Customers Get More than they Bargain For

Our customers know exactly what to expect when they do business with BA Precision Products:

COMMUNICATION, ATTENTION TO DETAIL, AND PROMISES MET.

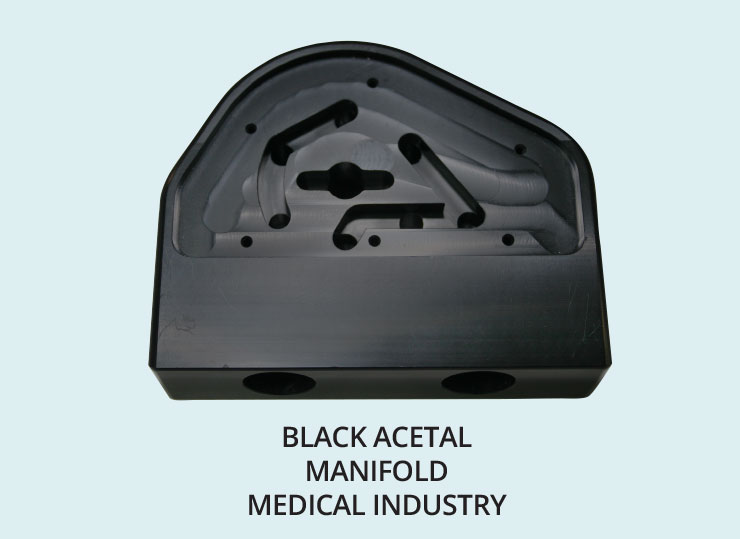

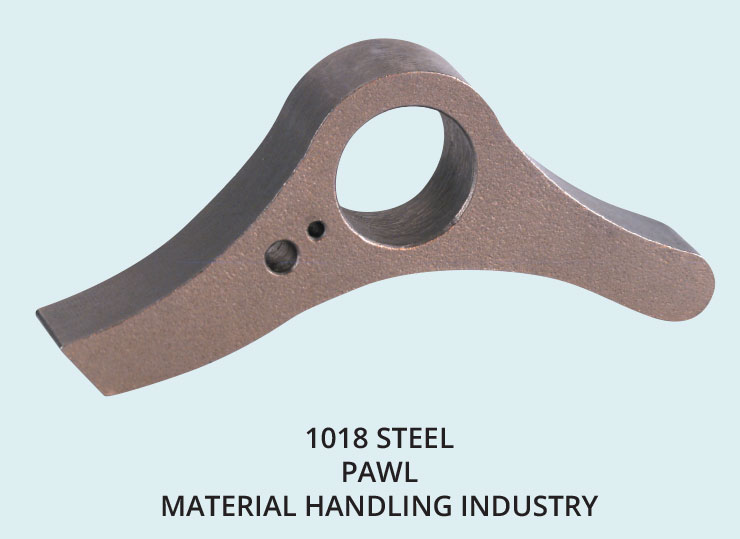

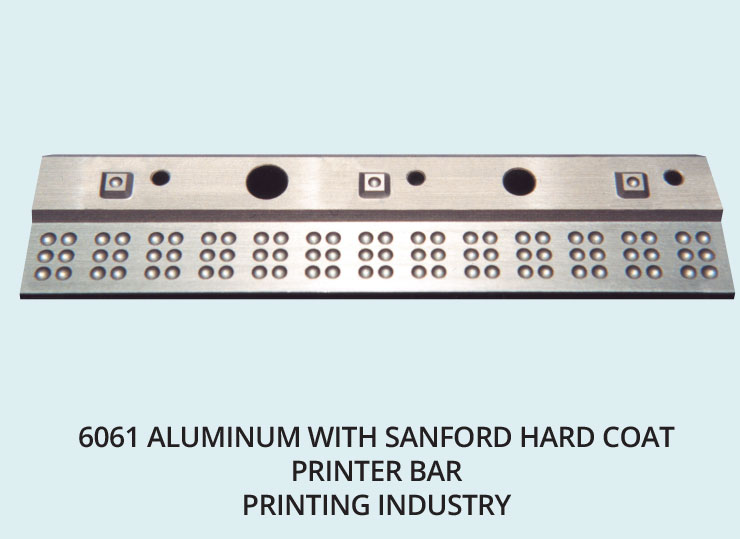

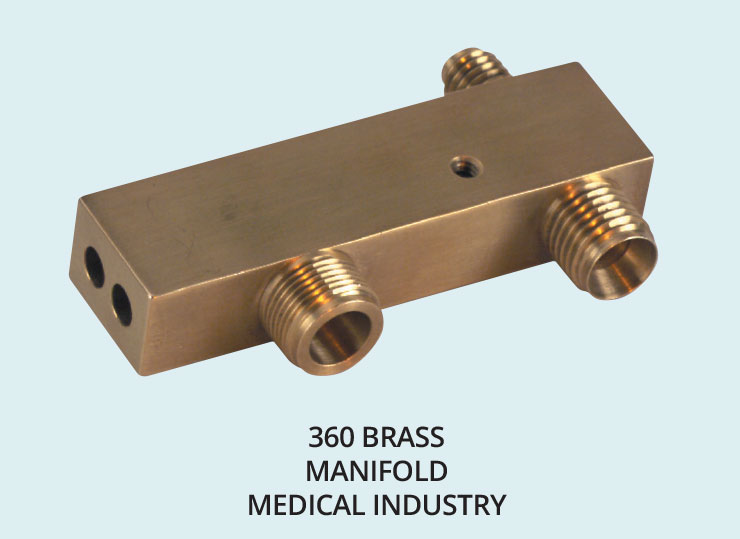

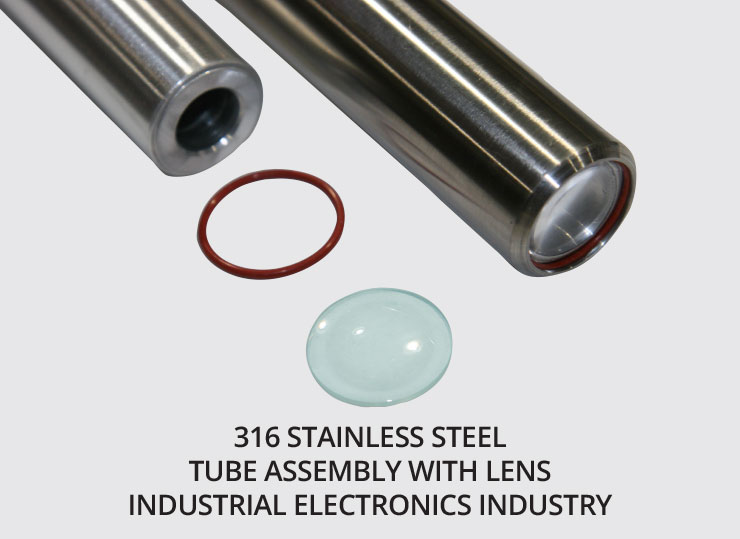

For nearly 30 years, we have served a diverse group of industries including industrial equipment, medical, outdoor recreation, marine, as well as many others. From the inception of every project, we review your requirements thoroughly and make manufacturing suggestions. We take this initial step very seriously because it can easily be the best way to reduce your total cost. Of course, in the final analysis, it is always up to you, our customer, to approve any changes that you feel may enhance your product.

At BA Precision, our greatest responsibility is to satisfy our customers. We look forward to having the opportunity to earn your trust.

About Us

BA Precision Products opened its doors in 1991. Since that time, our facility has grown to consist of 5000 square feet of modern, air-conditioned office and manufacturing space. We have become a leader in small parts production manufacturing, in part because we utilize the highest quality machines including Mori Seiki®, Kitamura®, Mazak® and Hardinge®.

We attribute our success to three basic principles:

COMMUNICATION:

The most important step in any manufacturing operation is understanding your requirements. We know from our many years of experience that the blueprint does not always tell the entire story. We strive to fully understand the form, fit, and function of your parts and how they interface with mating components. Our job is not complete until your parts work as planned!

A TEAM APPROACH. BA Precision has more than 100 years of combined manufacturing experience which helps us to ensure your job is processed as cost effectively as possible. Before jobs reach the shop floor, group leaders from each department agree on an acceptable way to process the job. This proactive team approach keeps our quality high and our deliveries on-time. Reject rates are under 1%, and we ship on-time over 95% of the time.

ATTENTION TO DETAIL:

ORGANIZATION. BA Precision utilizes Henning Visual Esti Track™ Software. This software allows us to quote jobs accurately and identify where bottlenecks have occurred in the past, thereby enabling us to focus on these critical areas to prevent inefficiencies in the future. Mastercam® programming software is used to aid in creating the most efficient machine code to process your parts. We have been using Mastercam® software since 1991, and it is updated every two years. We have the ability to import most file types including Solidworks, Autocad, IGES, DXF, DWG, Inventor, Solid Edge, STEP and STL.

INSPECTION. For every job that runs through our facility, we create an inspection schedule. This schedule lists every dimension, the associated tolerances, and most importantly, the frequency of checking those dimensions. Operators calibrate their gages before each run and perform checks throughout the manufacturing process to ensure accurate and timely deliveries.

PROMISES MET:

INTEGRATED MANUFACTURING. Very few small companies can boast of the integrated manufacturing that we have under our roof. We can process your job via Screw Machine, CNC Lathe, CNC Mill with Pallet Changer, Manual Mill, and/or Centerless Grinding. In the Lathe Department, we have single spindle, twin spindle twin turret, as well as live tooling options. A combination of these processes may be the most cost effective way to manufacture your part. Because we have the luxury of many options, we can save you the maximum amount of money while avoiding lengthy delays caused by outside sub-contractors.

Capabilities

Machine Specifications

| Service | Qty | Model/Type | Description |

|---|---|---|---|

| CNC MILLING | 2 | Kitamura® Mycenter | 24 station tool carousel, 20”X x 14”Y x 18”Z travels, Spark changer pallet changer, two second tool change, coolant through tool, 15,000 RPM spindle |

| 2 | Fadal Milling Centers | 16 station tool carousel 21"X x 16"Y x 16"Z travels | |

| MANUAL MILLING | 2 | Bridgeport® | with power feed |

| DRILLING | 2 | Jet | Drill press, ½" diameter capacity |

| AUTOMATIC TURNING | 3 | Brown and Sharpe Screw Machines | ¾" diameter capacity |

| CNC TURNING | 1 | Mori Seiki® ZL150S | Dual spindle, dual turret lathe, 1 ⅝" diameter capacity with LNS bar feeder |

| 1 | Mori Seiki® ZT1500Y | Dual spindle, dual turret lathe, with live tooling and 2" diameter bar capacity with LNS bar feeder | |

| 1 | Hardinge® Cobra CNC | 8" diameter capacity, LNS magazine bar loader | |

| 1 | Mazak® QT 20 | 2" diameter bar capacity, LNS magazine bar loader | |

| GRINDING | 1 | Royalmaster | Centerless grinder, 12" x 4", 1½" diameter capacity |

| SAWING | 1 | HEM® Sidewinder | Auto-feed band saw with 12' bar feeder |

| TOOLING | 1 | Boyar-Schultz | Surface grinder, 6" x 11" |

| 1 | Tool Room | Hardinge® DV-59 | |

| 1 | Glendo | Carbide sharpener | |

| 1 | Darex | Drill sharpener | |

| FINISHING | 1 | Sweco | Vibratory tumbler, 3 cubic feet capacity |

| QUALITY CONTROL | Digital micrometers, digital verniers, height gages, pin gages, Jo blocks. Assorted thread gages and specific gages for customer applications | ||

| 1 | Mitutoyo | Optical comparator | |

| COMPUTER | 1 | Mastercam® | Programming system, version 2017 |

| 1 | Henning | Visual EstiTrack™, shop management system | |

| MISCELLANEOUS | 1 | Toyota | Forklift |

| 1 | Telesis | Dot impact programmable marker |

Contact Us

561.750.9778 FACTORY

561.391.9440 OFFICE

561.859.3400 CELL

561.394.6728 FAX

gary@baprecision.com E-MAIL

baprecision.com WEBSITE

2920 NW 2nd Avenue, Bay 4

Boca Raton, Florida 33431

Business Hours

Monday-Friday: 8:30 am - 6 pm